MultiPHS: The Ultimate 3D Printing Post-Processing Workstation

Overview

MultiPHS is crafted for professionals in 3D printing, where versatility is paramount. It seamlessly integrates into existing systems, offering a flexible post-processing solution for various needs.

Key Features

Easy and Fast Material Change

- Adaptability to Finegrain Polyamides: Different mechanical properties after sintering require varying cleaning depths.

- Efficient Cleaning: Key spaces are easily accessible, allowing for a complete cleaning in just 30 minutes with included vacuum and accessories.

Multi-Material Compatibility

- Versatile Settings: Features 6 settings to handle a range of SLS powders, including third-party materials.

- Broad Application Spectrum: Supports numerous types of SLS printing materials for enhanced versatility.

Universal Printer Compatibility

- Sinterits and More: Compatible with all Sinterits printers and other compact or industrial SLS printers.

- Flexible Integration: Designed to fit seamlessly into any professional 3D printing setup.

Efficient Powder Recovery

- High Recovery Rate: Up to 95% powder recovery in a 20-liter container.

- Resourceful Reuse: Enables reusing powder in subsequent prints with an easy mix process.

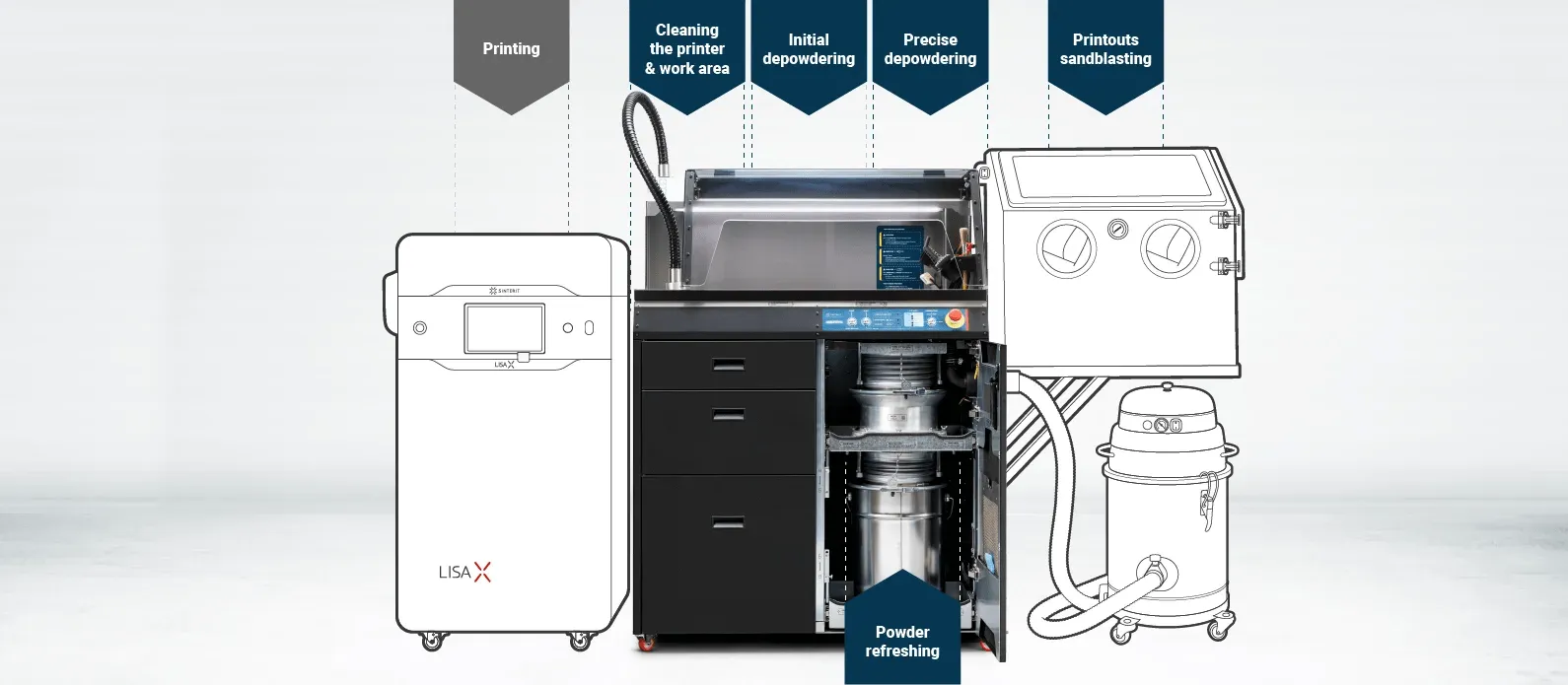

Advanced Powder Management

- Synchronized System: Works in tandem with Sinterits printer, ATEX vacuum, and sandblaster for optimal material control.

- Cost-Effective Recovery: Advanced system for material reuse and cost reduction.

Intuitive Interface

- User-Friendly Panel: Offers 5 sifting programs for different materials with overload and depowdering sensors.

- Peripheral Control: Manages connected devices like vacuum and sandblaster.

Adjustable Workspace

- Flexible Design: Adapts to large print cakes from various printers.

- Quick Setup: Transition between systems in minutes with compatible accessories and tools holder.

Antidust Cover

- Safety Compliant: Plexiglass cover minimizes powder spread and ensures user safety against inhalation.

Watch the Workflow

Discover the efficiency and ease of the MultiPHS in action.

Specifications

Physical Dimensions

- Size: 1000 x 700 x 1700 mm / 39.4 x 27.6 x 66.9 inches

- Weight: 157 kg / 346.2 lbs

- Installation Space: 1700 x 2200 x 1800 mm / 66.9 x 86.6 x 70.9 inches

Electrical Requirements

- Voltage: 230 V AC, 50/60 Hz or 110 V AC, 50/60 Hz

- Power Supply: 110/230 V AC, 12 VDC 6.67 A, 80W

Full Specification

- Available in PDF format.

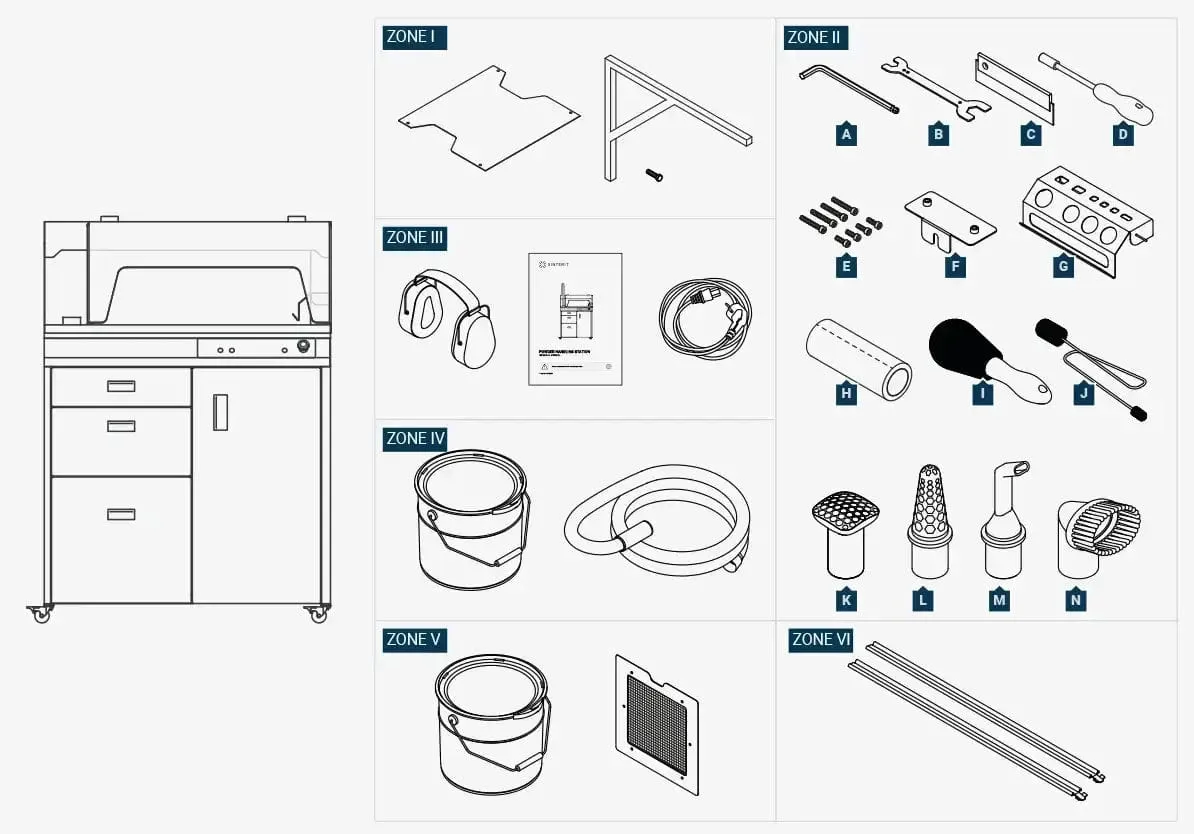

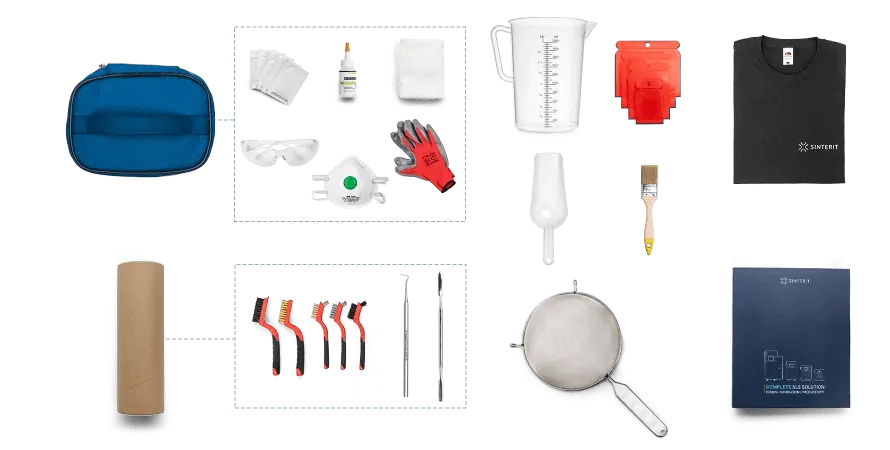

What's Included?

- Zones I-VI: Comprehensive components ranging from sandblaster shelf screws to the MultiPHS user manual, including various nozzles, brushes, and accessories for complete functionality.

FAQ

Workflow and Efficiency

- Post-Processing Workflow: Details on depowdering, sifting, and powder refreshing processes, including duration and steps.

- Mess Management: Techniques to limit powder contact and spread during post-processing.

Sifting Module Functionality

- Efficient Sieving: Located under the worktop for optimal powder management.

Cost Optimization

- PHS Advantages: Explains how the Powder Handling Station contributes to cost savings in SLS printing.

Client Testimonials

- Experiences and endorsements from professionals in various fields, illustrating the practical benefits and efficiency of using MultiPHS.

Additional Resources

- Dedicated Powder Tools: Information on complementary equipment for enhanced printing and post-processing.

- Free Ebook: Tips and strategies for reducing SLS 3D printing costs.

Contact Us

- Tailored Assistance: Provide your requirements for personalized guidance.

- Prompt Response: Our team will reach out immediately after receiving your inquiry.

MultiPHS is not just a workstation; it's a comprehensive solution for optimizing your 3D printing post-processing needs, ensuring efficiency, versatility, and cost-effectiveness.